Advanced ColorSoft®

|

|

The basic design of our advanced color matching programs has evolved from more than 30 man years of PC

color software development. Our design objective was to develop a master software set to:

- Control multiple instrument color

measurements

- Calculate color data and color QC

functions

- Create, manipulate and store color

data

- Calibrate colorants to allow a wide

range of

industries to formulate and correct colors

|

|

From the master program we provide

the ColorSoft user the tools to

build the system to meet their specific requirements. We provide both full systems with

all capabilities or limited software sets with one or more functions. Our full ColorSoft Windows program is offered as software modules:

|

- Basic System for Color Measurement, Data

Storage and QC Module

- Formulation & Batch Correction

Module

- Colorant Characterization Module

- Formula Storage Module

|

|

Spectrophotometer Measurement Control - senses the

instrument and its calibration condition, receives spectral data, allows averaging,

positioning of samples and identification of standard trials. The program is provided with

the special instrument interface communications protocol depending on the instrument

requirements. A variety of calibration techniques are provided in addition to the

instrument manufacturer’s recommended technique. |

|

|

Color Formulation Matching Module - Allows color matching by combinatorial match prediction using all

possible combinations from a full range of colorants or user selected colorants. Matches are sorted by cost and best color by single Illuminant or

by the

least metameric match. Allows

manual match and semiautomatic formula prediction using operator selected colorant

combinations from a range of colorants. Allows the addition of a waste batch as a new

colorant and correction of neares "SEARCH"candidate

from existing proven color match formulations.

|

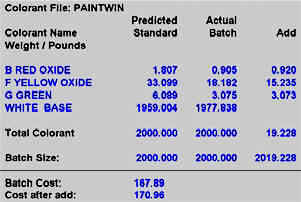

Batch Correction Module - Predicts additions required to correct batch

from user entered formula or by automatic calculation based on colorants used. Also will

do automatic analysis of unknown batches and predict possible corrections. Provides

reformulation scaling for test batches to production batches. Includes manual add to

manually adjust batch and estimate results for batches and waste. Allows "reduction

of add " based on color tolerance. Provides functions to integrate corrections with

initial matches and save corrected formulas.

|

|

|

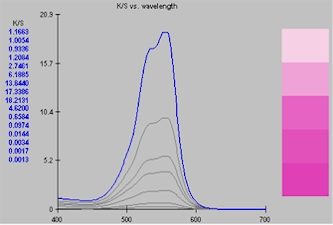

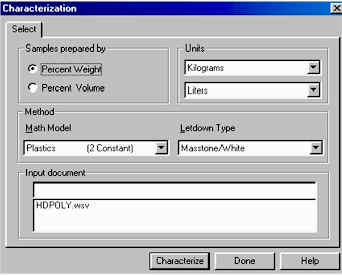

Colorant Characterization Module

Builds color matching K and S and/or K/S files that allow the user to characterize their colorants for matching and correction;provides 9 sample characterization methods, includes automated techniques for less experienced operators. Multiple Resins, bases, whites, substrates can be calibrated for specific colormetric functions in addition to colorants (dyes & pigments). The software simulates color letdowns on-screen. Allows colorant data base adjustment for new colorant batches and for quick check of colorant candidates for recycle. Multiple databases can be built to meet various application requirements.

|

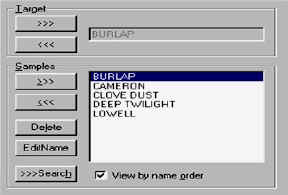

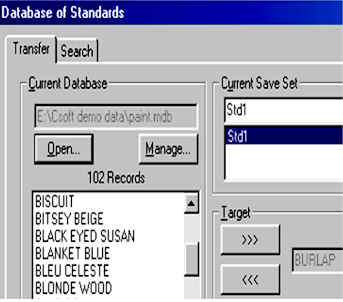

| Color Library - Allows user to create one or more library

of color standards (Basic Module), with formula add on (Formula Storage Module). Allows search for closest matches and recall of formulas with color

standards. Offers a wide range of base to colorant options based on weight and volume

calculations. Searches can be based on any color criteria selected. Color Library is provided

in MS ACCESS format. |

|

|

| |

Color

Measurement- Color

instrument interface is supplied in the Basic

System Module and is required for all operations providing communication protocol to one or

more color instruments. ColorSoft is designed to communicate with a variety of color instruments, both Spectrophotometers and Colorimeters, via standard USB or RS232 serial interface.

The instrument drivers control

calibration logic, demanding calibration each time the instrument is

turned on (utilizing the instrument manufacturer’s methodology or other

optional methods); hold current calibration, initiate color measurements,

receive reflection or transmission data from the instrument, save the

data, allow averaging of 2 or more measurements into one measurement, run

diagnostics and perform electronic switching from one instrument condition

to another, if the instrument is designed to do so. |

We provide software to work with most color instruments that communicate 10nm and 20nm data via RS232 serial lines with user selectable 400 to 700

nm or 360 to 780 nm extended range.

ColorTec also supplies complete new systems working with the ColorTec "family" of color instruments and will mix software offerings for older color instruments as well as new

full systems.

|

|

Data Management offers

universal ODBC compatible (MS Access) data

management in a 64 bit Windows environment. We develop 4 types of data bases in our software.

The first is called a Saved Set; it contains a standard and multiple trials, including for each measurement, ID ( 40

character A/N), notes about the measurement, reflection data from the color measurements

stored as the instrument out-puts the data, in 10nm or 20nm spectral format.

From the

reflectance data the system calculates X,Y,Z, in 3 Illuminant weightings of the 14

illuminants offered in the basic software. 2 and 10 degree observer math is user

selectable. The colormetric calculation of choice is also stored with the record (we

currently support Hunter L,a,b, CIELAB, FMCII, CIELuv, XYZ/Yxy, CMC with settable ratio, Lch, CIE94 (CIEII) with settable K factors). These files are used to store and recall measurements for data

analysis, development of colorant files and for future formula prediction or correction. Save Set data is provided in the Basic System Module. |

The second database file type are Reflection Files (ODBC compatible) of unrelated color measurements with search functions. The structure of the color measurements are the same as

the Save Sets. Data can be moved from Reflection Files to Save Sets and back, on demand.

Often Reflection files are used to store Master Standards of data. Reflection Files are

useful to store fan deck colors with 2 fields of alpha numeric ID information, which

allows a color number in one field and a color name in the second field.

You can recall

from this file, or measure a color and recall one or more close colors. This type of field

is useful in storing competitive color decks, recalling them and running a match, without

having the competitive color available at

the site. |

|

The third type of

database files are Formula Storage Files (ODBC

compatible), which are files that allow you to store the

quantities of colorants and base materials in weight and/or volume which are proven to

produce a defined color measurement. This feature becomes a valuable asset as an

electronic formula book for your standard colors.

ColorSoft provides the tools

to tie a Formulation File to a Reflectance

File and to one or more a Colorant

files. Utilizing Search functions use this feature for a measure and search function. This

allows using the closest color as a match, or using the components of the closest color as

the staring point for a rematch.

Formulas can be recalled by ID and scaled to various

batch sizes, switched to weight and/or volume in a range of outputs (weight= ounces,

pounds, grams, Kilograms, grains ) (volume= ounces, settable shots, quarts, gallons,

millimeters, liters). Allows calculation of VOC if base data is entered in colorant file. Formula

Storage Files are included as part of the Formula Storage module. |

The fourth type of database file

are K and S, or K/S Colorant Files developed in our master system using the proprietary technology of the Colorant Characterization module.

For opaque materials ColorSoft has the logic to use samples

prepared using white bases and colorants based on using, black, and white mixtures; black,

white, and mass tone mixtures; a series of white let downs; and black with a series of

white letdowns and a mass tone mixture.

We can use one or more of the K&S colorant

calibration techniques in any one colorant file. Multiple colorant files are allowed, each

using separate colorant calibration tools.

For specialty Plastics, some Ceramics, some

Cosmetics, Cement and some Coatings applications, resins can be calibrated to take into

account the color contribution of the non colorant base portion of a mix.

Multi

concentration K/S Textile and Clear Ink colorant characterization and clear solution (or

clear film) mixing colorant characterization based on Beers Law are also supplied and

supported. |

|

System Logic is designed to allow the user and ColorTec support

engineer to set specific requirements for data analysis, color matching, colorant

calibration and color correction. The setup for data analysis can be done on a master

system while developing colorant data bases and organizing the system for the other

plants.

The systems sent to the other plants can then utilize colorant data bases

developed on the master system as long as the instrument metamerism is minimized. Changes

can be made in the field by sending new files or software updates to each of the locations. The satellite locations can purchase just the Basic QC module and the Formulation & Batch Correction module.

This allows development flexibility at the central lab and still maximizes

efficiency of sample preparation for plant support. If local plants still need the freedom

to use different colorants to meet local conditions they will need the ColorSoft Colorant Characterization module. |

Networking of Data and Operations is planned into the ColorSoft software design. We can install the software on single unit

systems, Local Area Networks based on Token Ring or Star configurations (Novell or NT) or

Peer to Peer LANS.

We also offer unique "Work Only" station licenses that can be

used to extend the use of your ColorSoft investment to allow multi applications using one color instrument with

multiple stations in the local plant. This allows the technician to do day to day work on

the main station and still allow you to recall color data or do other color operations at

a second station.

Some ColorSoft users use the

"Work Only" license on a portable computer to take color data to a customer for

review or to allow a remote modem call in to support plant operations trouble shooting in

off hours or while a key technical person is traveling.

|

Success of Color Formulation

Systems as measured by the accuracy and

repeatability of color matches is highly dependent on the quality of instrument, its light

source and the quality of the colorant calibration samples and the precision of sample

measurement procedure and the accuracy of the weigh ups including the precision and

minimum resolution of the weigh scales, the consistency and the quality of the formulation

prediction, rather than the software.

ColorTec’s objective is to optimize

our software matching results to provide the best match that each type of color instrument

is capable. If the database samples are well made, the color instruments of good quality,

the operator carefully measures the sample, you can expect color matches with color accuracy well below the visual threshold

with a ColorSoft System. On

going results are highly dependent on the color consistency of the materials used for

formula prediction and correction. |

|

ColorSoft® is a registered

trademark of ColorTec Associates, Inc., other manufacturers trade marks acknowledged; the

software is licensed for use of a single computer to the original purchaser, multiple

instruments are allowed. |